As a young, future-focused company, our freshness and innovation are our greatest strengths. But this is no start-up. METMO’s dynamic workforce contains both modern visionaries and experts with centuries of combined industry experience behind them, guaranteeing the perfect blend of smooth, well-worked processes and youthful creativity.

Meanwhile, our secure funding model – based on the participation of private international investors – gives our customers that extra peace of mind: we may be new, but we’re here to stay.

Put away the paintbrush. Our supremely-efficient workshop provides you with the flexibility to customize metal parts and products in a vast range of colors. With fully-automated, state-of-the-art powder coating equipment you can be sure that our offering represents the pinnacle of both quality and execution.

Made to measure. The metal for our height-adjustable systems is cut down to size using the industry-leading Trumpf laser cutter. Our ambitious investment into first-class industrial technology facilitates the creation of over half a million individual table legs per year: each crafted with performance, durability, and style as the ultimate priorities.

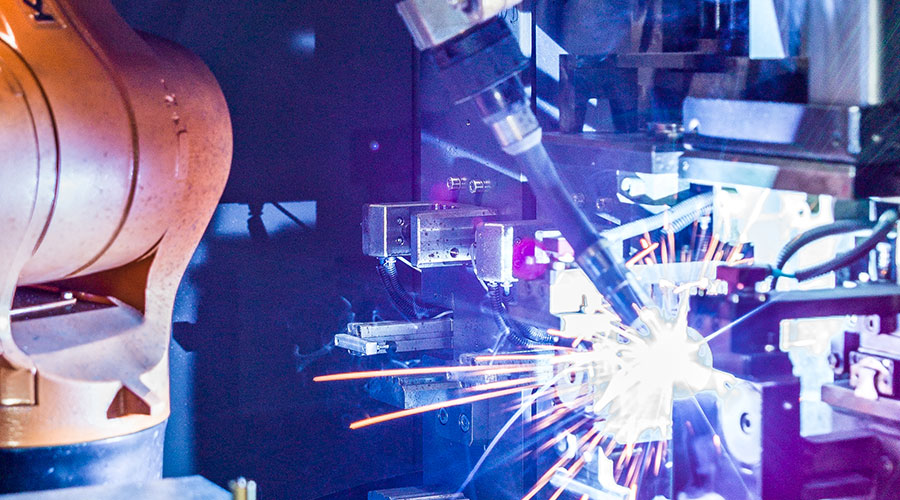

White-hot technology. Our welding cell is central to our ultramodern, precision-focused metalwork services. Our talented personnel and superb equipment form a perfect blend: resulting in seamless connections between an extensive range of legs, frames, and feet for adjustable office furniture.